Add to Cart

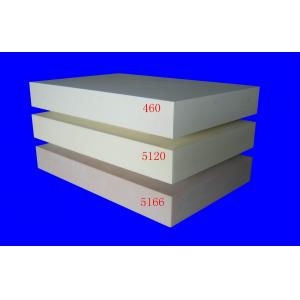

High Strength Epoxy Resin Board For Tooling Making , Polyurethane Model Board

DESCRIPTION

LihongTooling Board has been developed as a polyurethane based material for model and tool making and the manufacturing of checking fixtures and test units. Due to a special specification and a manufacturing method optimized over many years, it is possible to retain the product qualities even in the case of large board dimensions.

LiHongTooling Board is especially noteworthy for its smooth and homogeneous surface combined with an even cell structure. It has a high edge stability, small thermal expansion coefficient, low dust formation when being machined, no known physiological effects and odeurs or smell. The range consists of 15 different types, varying in density between 600 - 1700 kg m3. There are 20 different dimensions to a maximum of 1500x500 mm and thicknesses of up to 200 mm are available. Larger blocks can be achieved when bonding several blocks to eachother.

PolyurethaneTooling board, the toughness, environmental protection, hardness, size stability, temperature tolerance, physical properties such as compressive strength, bending strength is quite good.

We are quietly supporting these industries, automobiles, high-speed rail, shipbuilding, aviation, ceramics, foundry industry and daily necessities manufacturing and related industrieschecking fixtures, mold, wind power and yacht . Maybe we are also suitable for your product, can try, may have unexpected harvest.

Introduction

LH Tooling boards take the place of wood and metal in models, patterns, molds, jigs and fixtures.

They are lighter and more economical than steel and aluminum. They also do not suffer from the grain and poor dimensional stability of wood.

Tooling boards can be bonded together to form larger blanks and large blocks from which models or tools can be CNC-machined. The boards are easily mechanically workable with low dust formation.

Tooling boards are useful for creating durable, reusable tools, prototypes, models and patterns with a CNC machine for use in the motor sport and automotive industries. Selecting the most fit for purpose tooling board will reduce residual particles for easy cleanup, have excellent dimensional stability and maintain tolerances even when exposed to temperature and humidity extremes.

USES

1. Design studies

2. CNC program proving/testing.

3. Building Landscapes/Features in architectural and scenario models

4. Forming a mould tool for prototyping short runs of composite parts.

5. Use for jigs, fixtures, foundry patterns, core boxes.vacuum forming molds and all kinds of models.